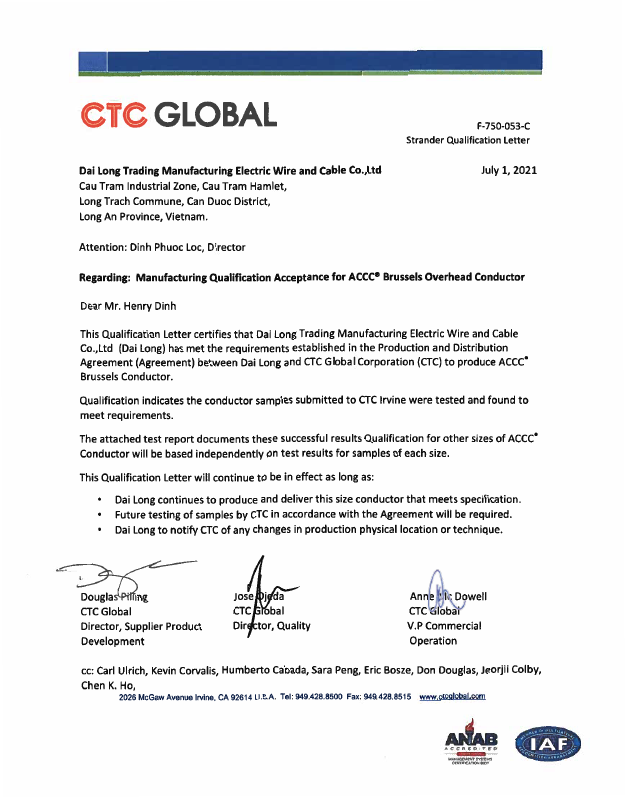

DAI LONG TRADING MANUFACTURING ELECTRIC WIRE AND CABLE CO., LTD (DAI LONG) IS A TRUSTED PARTNER IN VIETNAM THAT HAS BEEN AUTHORIZED BY CTC GLOBAL GROUP (USA) TO USE COMPOSITE CORE TO PRODUCTION AND TRADING CABLE PRODUCTS ACCC® SUPERTHERMAL ALUM

- In 2020, the Covid-19 pandemic broke out all over the world, affecting most industries, DAI LONG is no exception. But, with the orientation of developing DAI LONG to a new level. Therefore, on the path to mastering technology, production capacity and improving brand reputation in the electric cable manufacturing industry, DAI LONG’s team of engineers and employees have constantly researched and learned. , cooperate with leading industry experts of CTC Global Group to find new commercial values. Up to now, DAI LONG has officially researched, tested and successfully produced “ACCC® Superheated Aluminum Core Composite Cable“. July 1, 2021 became an important milestone when DAI LONG officially became a trusted partner of CTC Global Group (USA) in Vietnam, we are proud to affirm our production capacity and reputation. , the brand value of DAI LONG electric cables is the top choice of domestic and international investors.

.png)

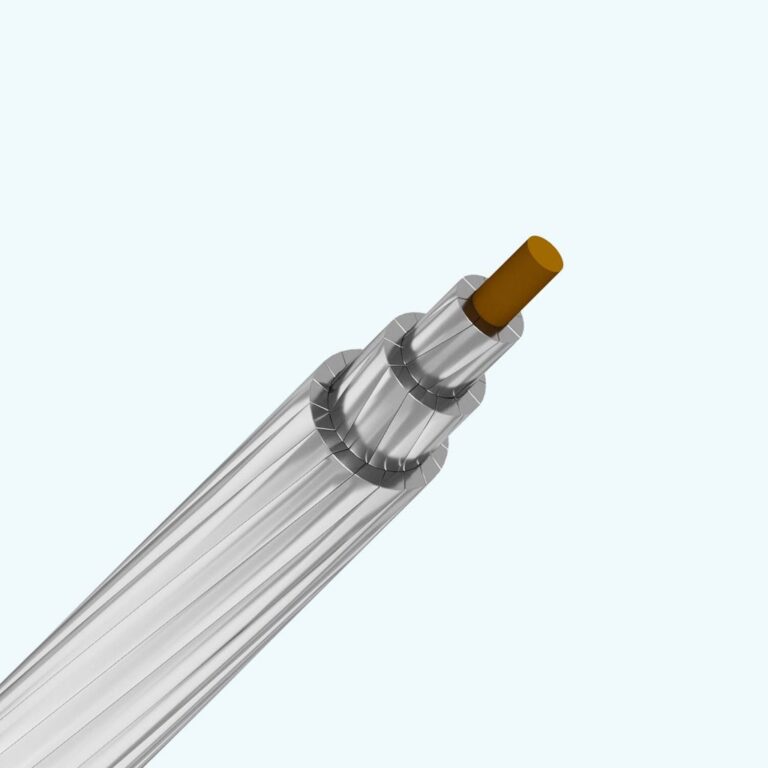

- The ACCC® Composite Core Aluminum Superheater Cable product is one of the patented achievements of CTC Global worldwide. With outstanding advantages, meeting strict standards and requirements in transmitting high voltage currents from 110kV to 500kV

- Compared to traditional ACSR cables and ACCC® Cables, they have the following outstanding advantages:

- The maximum temperature under normal operating conditions of the cable is 180 degrees Celsius;

- With the invention of a core with lighter materials , has allowed to increase the aluminum part up to 28%, helping to carry 2 times more current than traditional conductors while the wire weight remains unchanged;

- If compared to traditional ACSR cables with the same diameter and Under working conditions, ACCC® cables can reduce power loss from 20% to 40% depending on specifications thanks to the use of aluminum with high conductivity, larger conductive cross-section and no loss due to eddy currents;

- Capability The better bearing capacity of ACCC® Cable, self-shock absorption and high heat resistance allow increasing the length of post distance, reducing the number of posts used. In addition, the composite core has an extremely low thermal expansion coefficient (about 14% compared to the steel core), thus minimizing deflection;

- With high corrosion resistance and resistance to humid environmental conditions, salt water has helped increase cable life and maximize cost savings.

In addition, the composite core structure consists of parallel carbon fibers dipped in resin and covered with an epoxy-coated glass fiber layer, increasing resistance to electrochemical corrosion, protecting the carbon core from impact. of the environment. ACCC® cable opens up a way to optimally solve the inherent problems of current loss and reduce overload of the entire transmission system.

With these characteristics, ACCC® Cable fully meets the conditions to be considered a “low loss wire”, contributing to improving the load-carrying capacity of the system, ensuring safe power supply, Reliable for important loads.

ACCC aluminum composite core wire

ACCC aluminum composite core wire

DAI LONG uses CTC Global Group’s exclusive composite core to successfully produce and test ACCC® wire according to standards ASTM 987/B987-14, BS EN 50182, IEC 61395, IEC 62219, ASTM B 857 , BS EN 50540, ASTM B 193, ASTM B609, IEEE 738.

See product details here : https://dailongcable.com/san-pham/day-nhom-loi-composite-accc-2/

303 Dinh Duc Thien Street, Hamlet 9, Binh Chanh Commune,Ho Chi Minh City

303 Dinh Duc Thien Street, Hamlet 9, Binh Chanh Commune,Ho Chi Minh City (028) 37605134

(028) 37605134 (028) 37605622

(028) 37605622 dailong@dailongcable.com

dailong@dailongcable.com www.dailongcable.com

www.dailongcable.com